- Print

Work Orders

- Print

A Work Order is a record containing a set of instructions (Recipe) for work being done on a plant floor with one or more Parts. Work Orders include all the details about a specific job being performed.

A Work Order usually has a Customer and a Part Number assigned to it.

As work is performed, the Work Order completes the steps of the Recipe. At any Recipe step, one or more Parts can be marked as "Complete." Work Orders are orders for, and records of production which typically progresses in Steelhead through Workboards (see related articles).

Work Orders vs. Sales Orders

Work Orders are different from Sales Orders.

- Work Orders document particular tasks that must be completed in order to complete a Sales Order. They include processing information.

- Sales Orders are records of Purchase Orders placed to your company by Customers. They include pricing information.

- Sales Orders can include several Work Orders. You can use a Sales Order to group Work Orders together.

- A Work Order can only follow one Recipe. If you require several different Recipes as part of your Sales Order, you can group them as separate Work Orders under a single Sales Order.

Work Order Status

Work Orders have one of three statuses which may be selected to view separately:

1. A Staged Work Order is not ready to process - it either does not have a Recipe assigned to it yet, or does not have Parts yet. It's a rough draft.

2. An Active Work Order does have a Recipe and Part(s). Typically the work is underway.

3. A Complete Work Order is one which has had Parts assigned, all of which have been transferred out.

Assigning Work Orders to Customers

You can assign Work Orders to specific Customers. This allows you to:

- See all Work Orders associated with a specific Customer

- Provide Customers with limited access to active Work Order details in the Customer Portal (see related article)

Work Order Comments

Leave comments on Work Orders for others to see later on. These comments are specific to the work order.

Work order comments use Markdown formatting. Markdown allows for quickly creating notes without any need to move your fingers form your keyboard. With markdown, you can customize text without distracting toolbars or formatting options. Learn about basic markdown syntax here. A formatting Cheat Sheet and Guide is included in the Markdown Editor page.

Entering Work Order Comments from the Work Order Page

From a Work Order page, click the edit pencil icon in the title box, next to the Work Order number.

In the "Edit Work Order" dialog, there is a text box for Notes, for internal reference only, and a text box for Customer Facing Notes, which may be visible to the Customer in certain layouts such as in the Customer Portal. Enter whatever information you'd like to be referenced, and click SAVE.

Comments will now appear on the Work Order, as well as on Workboards.

Entering WO Comments from Workboards

- From a Workboard, click on the "Work Parts" button to open the work parts dialog for the parts.

- Note: even though the work parts dialog is only for specific parts and may not include the entire work order, comments left will show for the entire work order.

- Enter comments and click "Submit".

- Comments will now appear on the Work Parts slideout, as well as on the Work Order page.

- Work order comments and files can be shown on the invoicing page.

- Add work order comments and files to a work order.

- Invoice for the work order.

- An accordion-menu should appear and display this information.

Work Order Labels

Labels can be added to Work Orders to add additional information about the content, handling, priority, or status of the Work Order. Labels appear on the Work Order screen, on the scheduling screen, and on Workboards. Workboards can also show or hide Work Orders based on labels as well (See Using Labels on Workboards).

To add labels to a Work Order:

- Go to the Work Order you'd like to add the Labels to.

- Click the edit pencil icon on the top right of the title card.

- From the drop-down list, select the Label(s) that you want to apply.

- Click SAVE! to add the Labels to the Work Order.

Uncompleting Parts and Work Orders

In some cases, it is necessary to uncomplete a complete Work Order. In other cases, it is necessary to uncomplete only some Parts on a Work Order. This can happen if there is an error in the process that requires Rework, or if you need to re-create an Invoice for a Work Order (See Voiding and Adjusting Invoices).

If Purchase Order Items are accidentally marked as received, you can edit PO Lines with the edit pencil icon, uncheck the "Complete BOM Item" checkbox, and click SAVE. The items will be removed from received status.

Uncomplete a Work Order

If a Work Order is fully completed, you are able to uncomplete it, along with the Parts on it:

- On the Work Order page, click the button that says "CLICK TO UNCOMPLETE."

- Notice that no Parts appear in the Parts section.

- Go to the "Part Transfers" link under the Process Tree.

- Find the row where the Parts were completed. Confirm these are the Parts that you want to put back into the Process Tree. Use the "Revert Parts Transfer" icon to transfer the Parts back into production.

- Right now if you invoice for a Work Order and the Work Order is marked complete, it will not let you invoice for it a second time.

- If you invoice for a Work Order and the parts are not completed and the Work Order is still open, it is possible to bill for it again.

- However, Steelhead does warn you that you have already invoiced for the Parts so you are invoicing a second time.

Moving Parts to a New Work Order

Part/Work Order Reassignment

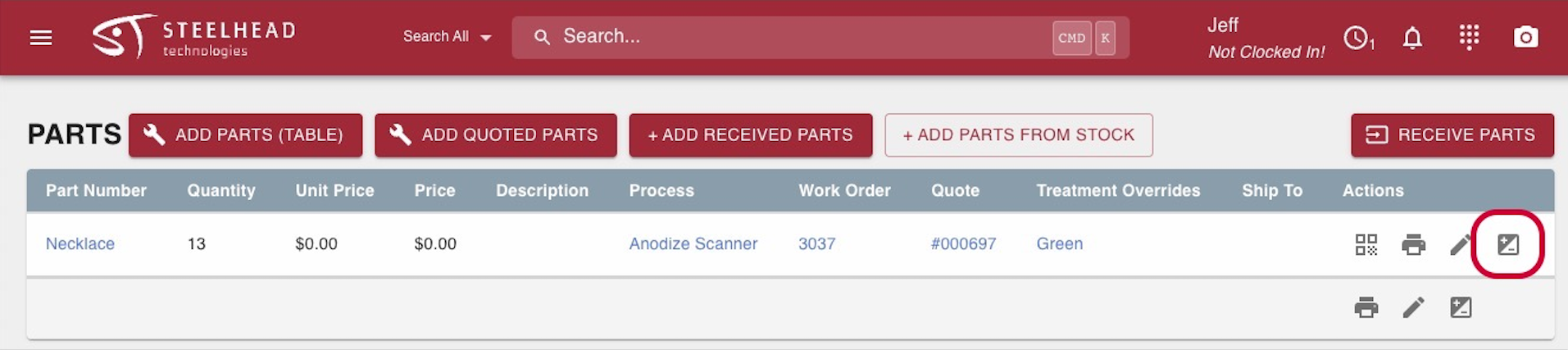

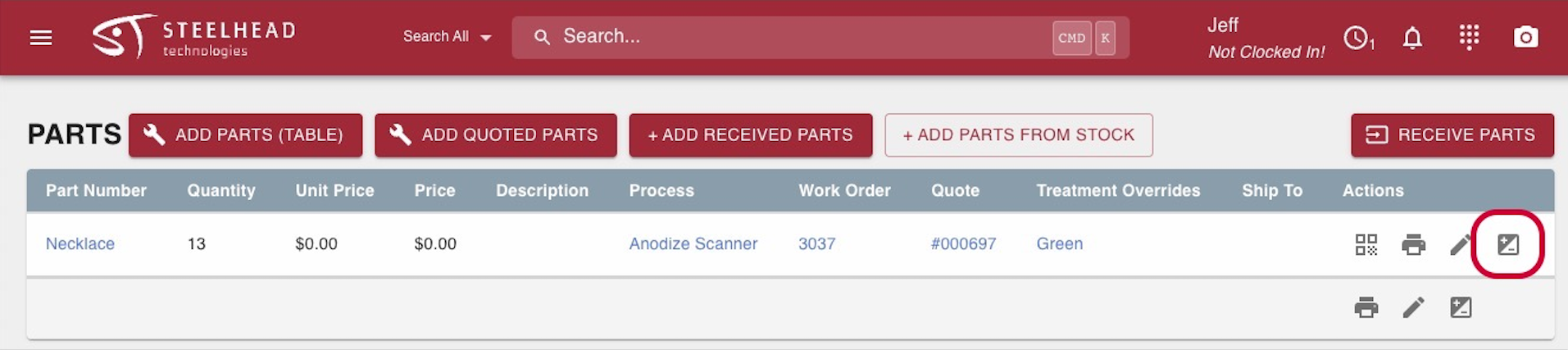

- To move Parts from one Work Order to another, go to the Sales Order and locate the parts that need to be assigned a new Work Order.

- Click on the +/- button next to the parts on the Work Order that you want to move.

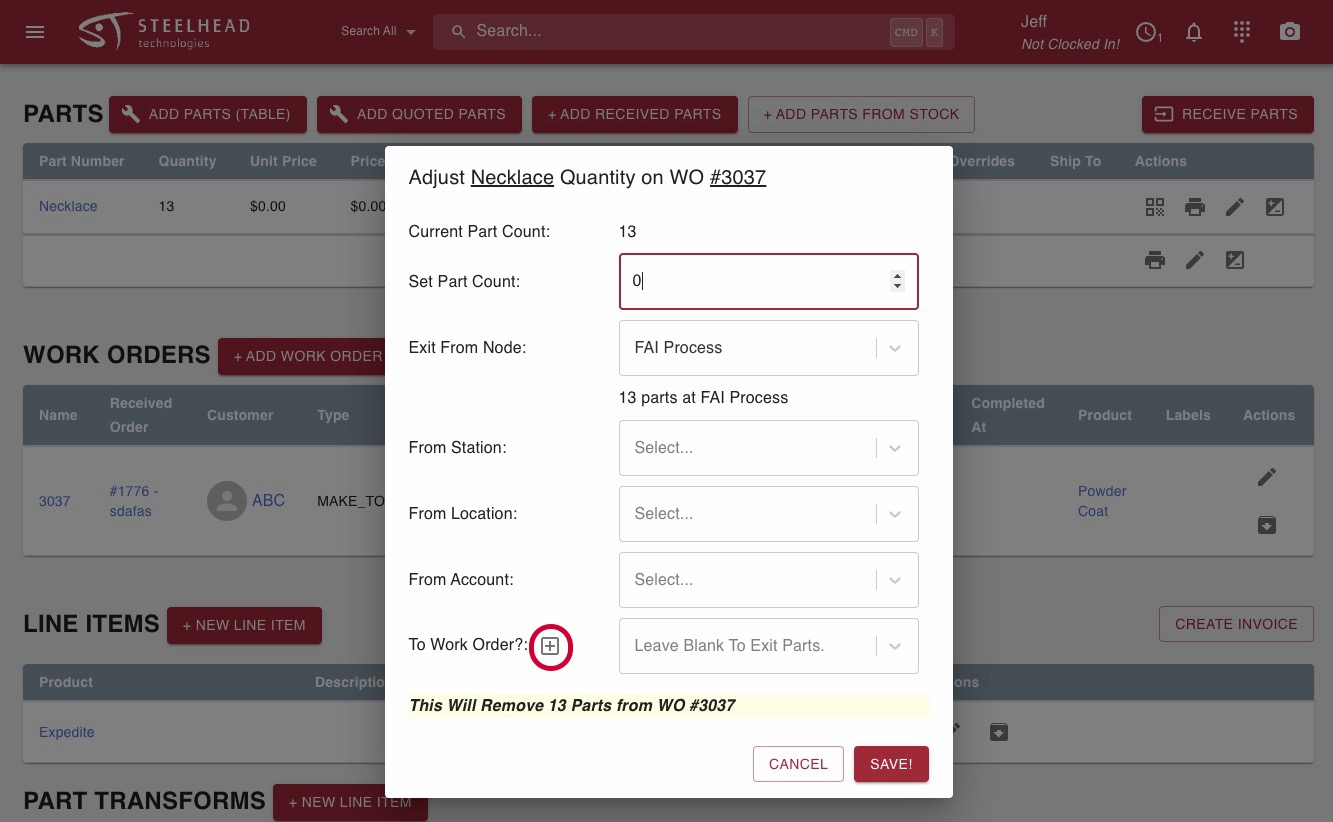

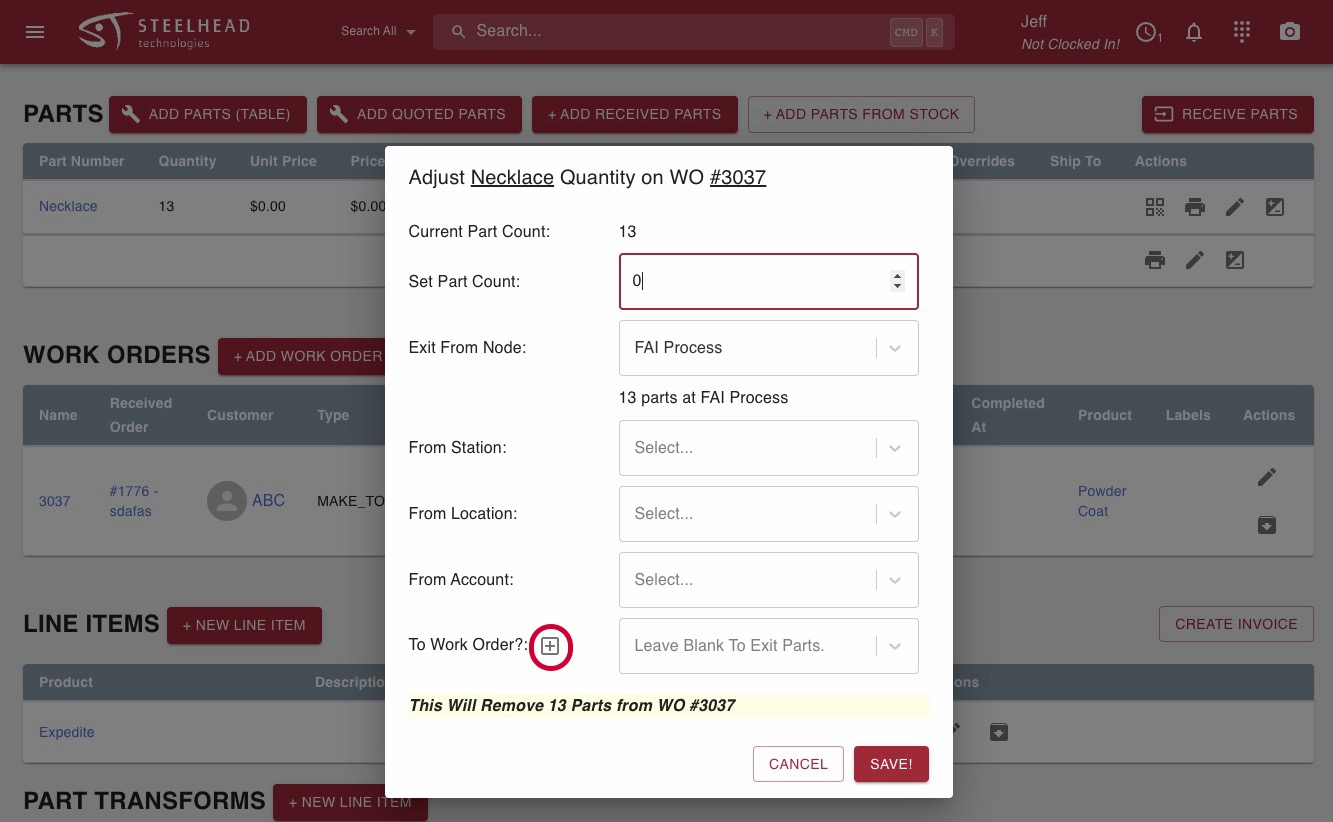

- Reduce the Part count by the number of parts that you wish to move (if you want to change the Work Order for all, set the part count to "0" to indicate that zero parts should remain on the current work order).

- More boxes will appear to ask you where you'd like the parts to go.

- Click the "+" button next to the "To Work Order?" question.

- Save and configure, then you will see all the Treatment options that you previously had.

- Include desired Treatments, pick the Inventory.

- This allows you to easily remove nodes from the existing Work Order's Recipe.

- Alternatively, you can also create a Recipe from an entirely new Process.

- This allows you to use your same quoted parts easily on an adjusted Work Order Recipe.

- This is especially nice for rework Work Orders that require only a portion of the previous Recipe to be re-done.

- Alternatively, you can also create a Recipe from an entirely new Process.

- This is pulling in from the original Treatment override so if an assigned color was red it's probably still going to be red.

- This can be edited or left as-is.

- This allows you to easily remove nodes from the existing Work Order's Recipe.

Now if you go back to the Sales Order, on the original Work Order there are no parts to complete. The Work Order and Processes will be corrected making Invoicing easier.

Before moving parts to a new Work Order, note that the part transfer labeled "complete" should be reverted if the parts are completed.

If you are trying to link an Invoice so it matches a pricing update made to a Quote, the parts will have to be moved to a newly created Work Order from which they can be treated properly.

Archiving Work Order:

Archiving the Work Order won't archive the Sales Order line because the Sales Order line strictly is what you will be invoicing/charging for.

- Therefore you can still charge for these parts even if they are not on a Work Order.

- To fully remove these parts you will have to archive the Sales Order line after you have moved parts from one Work Order to another.

See also:

Recipe Tree Editor and Work Order Creation How-To Video

Move Parts to a new Work Order How-To Video

Another video explaining the steps.