- Print

Create Treatments and Treatment Times

- Print

A Treatment is any work performed or value added to Parts. Treatments are typically done at Stations, for example, a Treatment called "Blue Powder" could be added to a Part at a Station called "Powder Booth."

Treatment names usually specify information about what work is to be done on a Part.

Some example Treatment names could include:

Work that indicates billed time

"Mask & Prep"

"Custom Packaging (Fragile)"

Inventory consumed on the treatment

"Blast - Fine Grit"

"Powder Blue RAL 12345"

Specifying Equipment / Settings

"Auto Oven 4hr"

"Zinc Flake Line"

Other process steps

"Unloading"

"Quality Inspection"

Treatment Groups are designations of similar Treatments joined in categories for organization. A example of a Treatment Group is "Paint" which could include all the specific paint Treatments such as "Blue Paint", "Black Paint", and "Pink Paint".

Creating Treatments

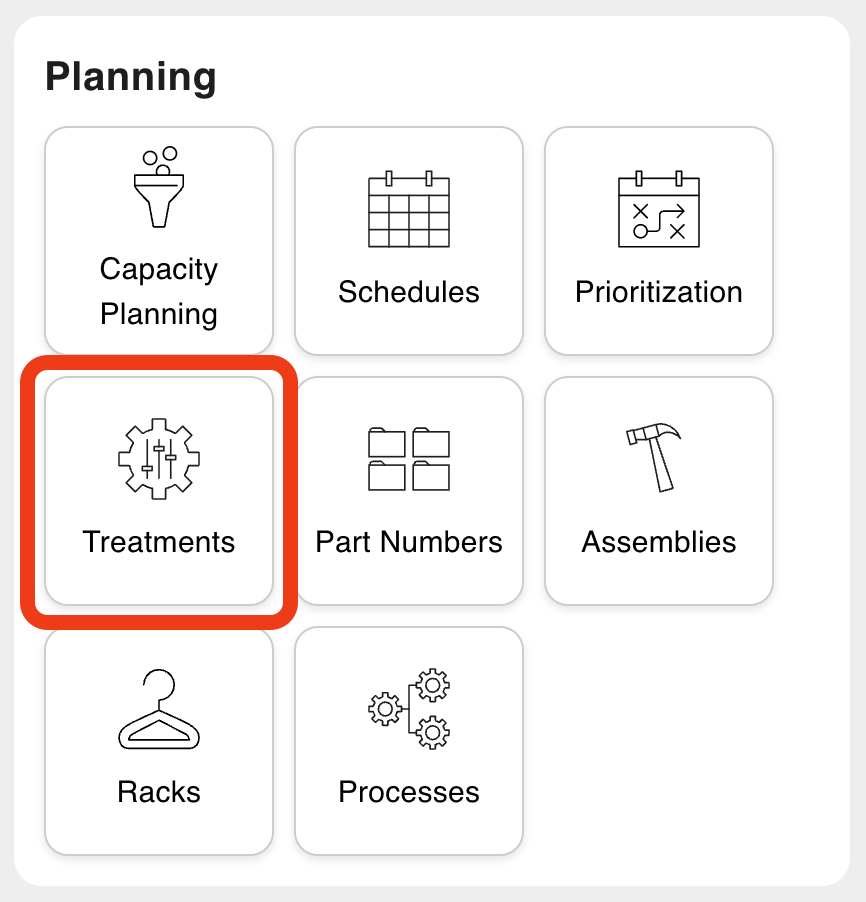

Treatments can be created in multiple or individually. Navigate to the Treatment Tile found in the Planning Section of the Steelhead Homepage to create and manage Treatments.

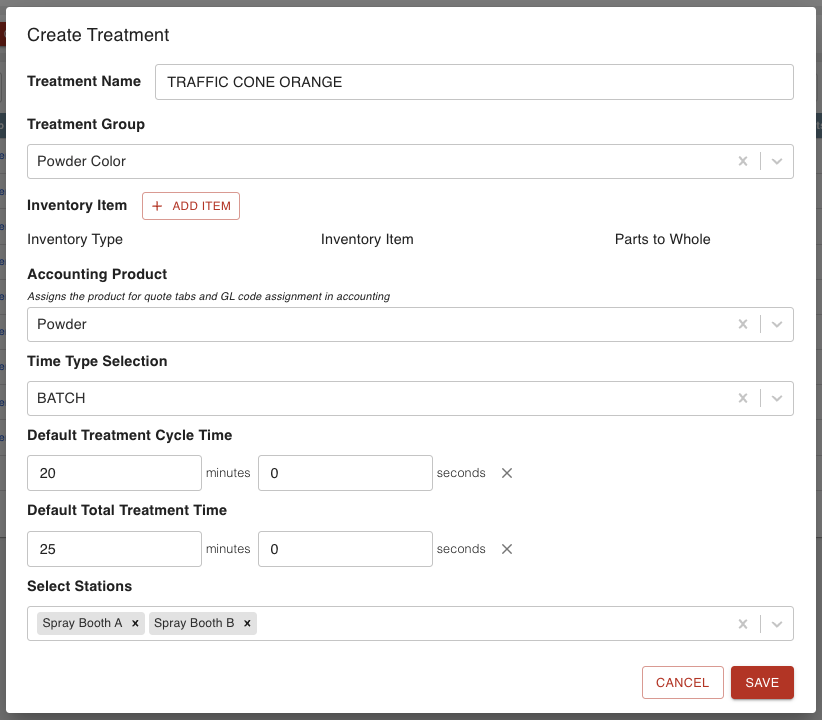

To create singular Treatments:

Click + CREATE SINGLE TREATMENT.

Create a Treatment Name.

Select a Treatment Group (or create new).

Click + ADD ITEM to add a Inventory Item (or multiple) that are associated with the Treatment.

For example, if the Treatment is "Hot Pink Paint", the Inventory Item "Hot Pink Paint" could be added here.

Select an Accounting Product, if applicable.

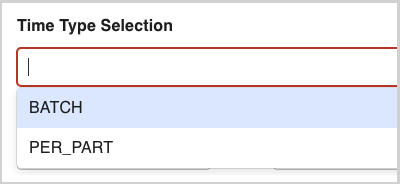

Make a Time Type Selection.

BATCH = timing for a group of Parts processed at once

PER_PART = timing for one part processed at once

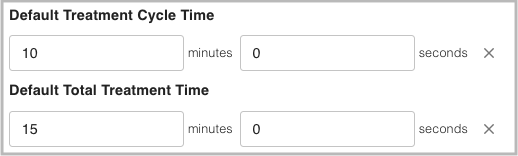

a. Input a Default Treatment Cycle Time.

b. Input a Default Treatment Total time.

Select Stations where the treatment is performed.

Click SAVE.

Treatment Time Units

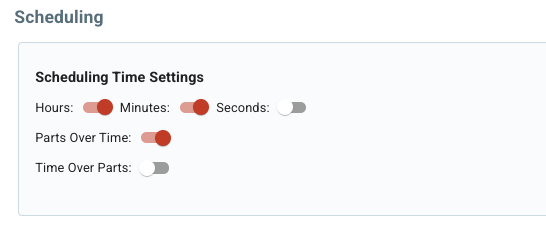

The time input units shown at Treatment creation are determined by the Domain Setting, "Scheduling Time Settings".

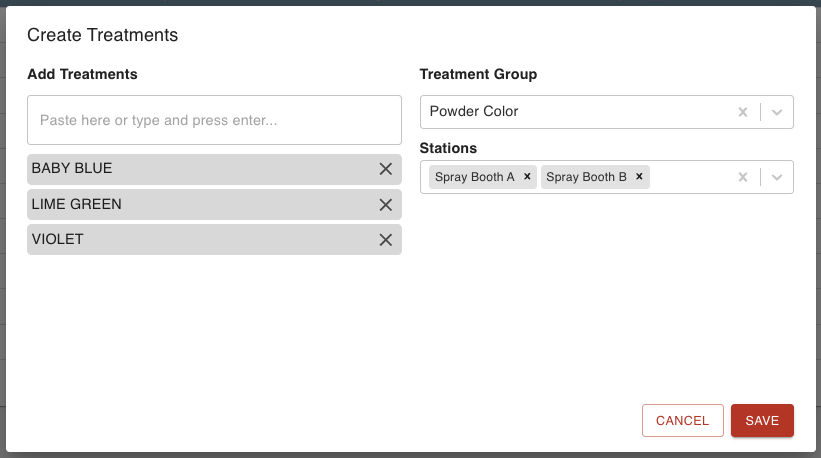

To create multiple Treatments:

Click + CREATE MANY TREATMENTS.

Add Treatments by typing each Treatment name and pressing [ENTER] on keyboard after each one.

Select the Treatment Group (or create new).

For example, apply the Treatment Group "Powder Color" to all of the different Powder Color Treatments being created.

Select any Stations to be associated with each of the Treatments.

For example, add all of the Spray Booth Stations to the new Powder Color Treatments.

Click SAVE.

Note: All fields and information in Treatments are optional, but recommended to fill out.

Creating Treatment Groups

Creating Treatment Groups is almost the same process as creating Treatments. The only difference is having to navigate to the "Treatment Groups" tab and click + CREATE TREATMENT GROUP.

Treatment Times

Filling out the Treatment times improves your documentation, production, Capacity Planning, and Scheduling capabilities. There are two types of Treatment times that reference how time is applied to Parts undergoing the Treatment.

Time Type Selection

Batch

The default time is applied to entire Batches of parts.

Example: You paint 10 Parts at a time because that's how many Parts fit on the Rack and it usually take 30 minutes to complete the Batch.

Per Part

The default time is applied to individual Parts.

Example: You blast Parts one at a time and it usually take about 10 minutes to blast each Part.

Default Treatment Times

A default Treatment time is the estimated time of completion for a Treatment to be performed. There are two types of default Treatment types:

Cycle Time

The amount of time that passes from the beginning of a Treatment until a new batch of Parts can be entered into a Station.

Total Time

The amount of time that passes while a Batch of Parts is treated, and available again for the next step.

Levels of Default Treatment Time Settings

There are numerous places where you can configure default Treatment Time settings. As described above, you can specify Treatment times when you create Treatments and Treatment Groups, but you can also add more specific times to Stations and Part Numbers which will override the general settings.

Setting correct Treatment Times is important for Quoting, Margins, Scheduling, Prioritization, etc.

The following is a list of precedence order from highest to lowest priority level:

Part Number Station Treatment

Part Number Treatment

Station Treatment

Station Treatment Group

Treatment

Treatment Group (base level)

Treatment Group Time Settings

Treatment Group time settings are the base level priority. The Treatment Group settings will be used only when there are no other settings available. For example, defaults for a "Powder Color" Treatment Group could be set to 15 minutes if it generally takes that long to process parts for that type of treatment.

Treatment Time Settings

The next level is Treatment specific time settings. For example, processing parts for the "Blue" Treatment takes a bit quicker than other Treatments in the group. The Treatment default time could be set for 10 minutes, which would override the Treatment Group default of 20 minutes.

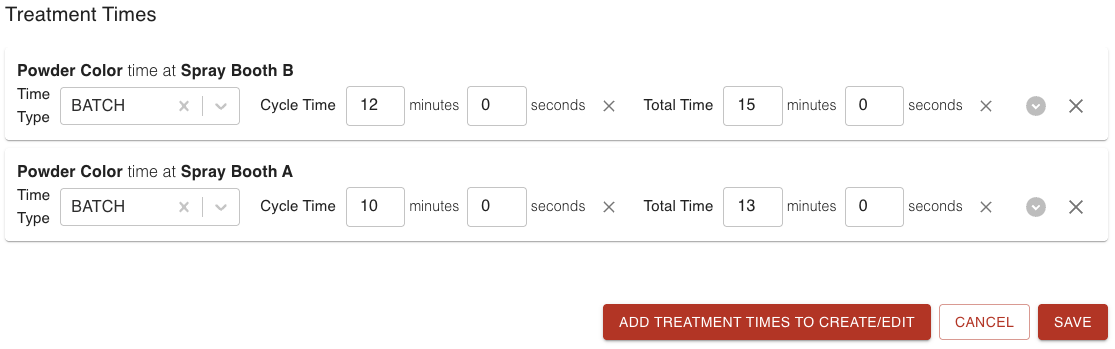

Station Treatment Group Time Settings

The next level of specificity is Station Treatment Group time settings. This setting is for Treatments of a Treatment Group being completed at a specific Station. For example, "Spray Booth A" Station can be set to take 15 minutes to complete a treatment of the "Powder Color" Treatment Group. This time would override the above times, if the part is routed to the particular station.

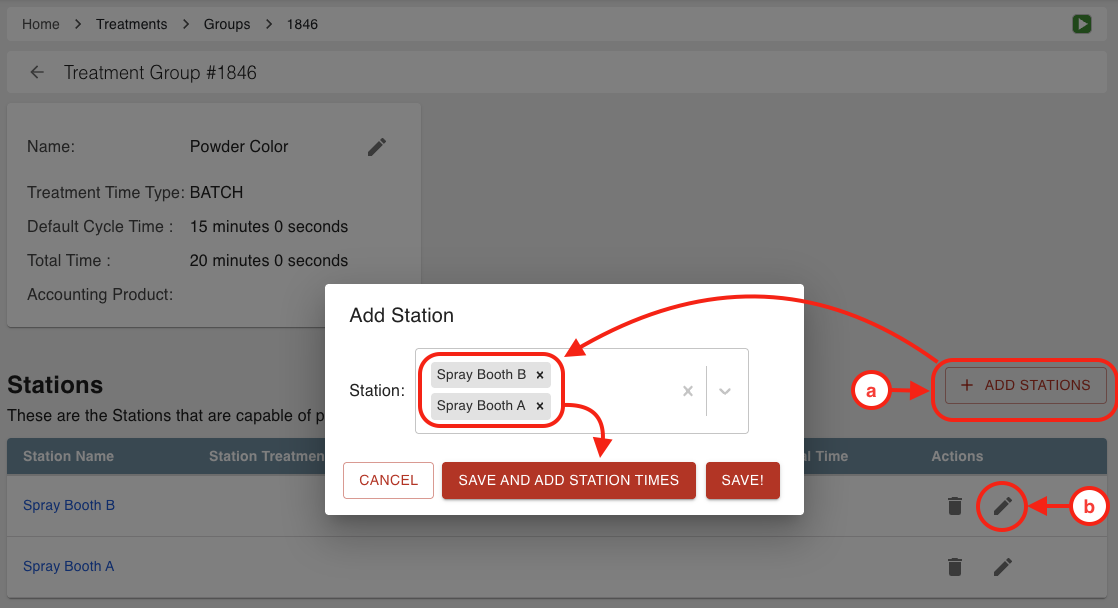

To configure the Station Treatment Group time settings:

Navigate to the Treatments Tile found in the Planning section of the Steelhead Homepage.

Click the Treatment Group tab and open a desired Treatment Group Page.

Scroll to the "Stations" section.

Add or edit a Station Treatment Time.

Click + ADD STATION, select the Station, then click SAVE AND ADD STATION TIMES

ORClick the Edit pencil icon next to an existing Station.

Configure the time settings for any Stations that were selected.

Click SAVE.

Station Treatment Time Settings

Station Treatment time settings will override all previous settings. This is when a specific Treatment occurs at a specific Station. Continuing with the above examples, the time for "Blue" Treatment being done at "Spray Booth A" could be configured as 20 minutes. This time would take priority over the settings listed above.

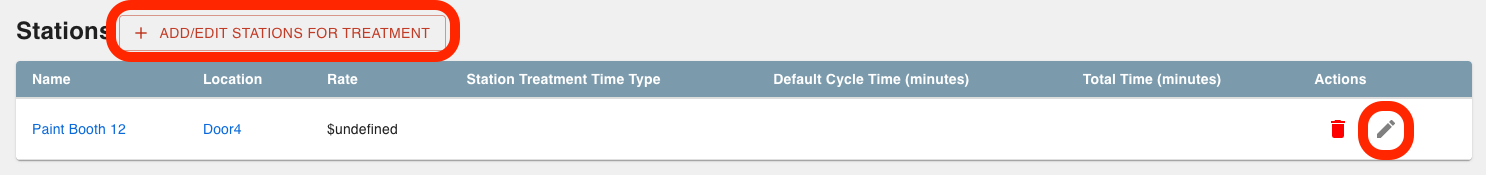

To configure the Station Treatment time settings:

Navigate to the "Treatments" Tile found in the "Planning" section of the Steelhead Homepage.

Enter a desired Treatment Page.

Scroll to the "Stations" section.

Add or edit a Station by clicking + ADD/EDIT STATIONS FOR TREATMENT or click the Edit pencil icon.

Configure the time settings.

Click SAVE.

Part Number Treatment Time Settings

The next level of priority is Part Number Treatment time settings. This is for specific Part Numbers that go through a Treatment. For example, you can specify that a "3-IN-BOLT" takes only 10 minutes to be treated with "Black Paint".

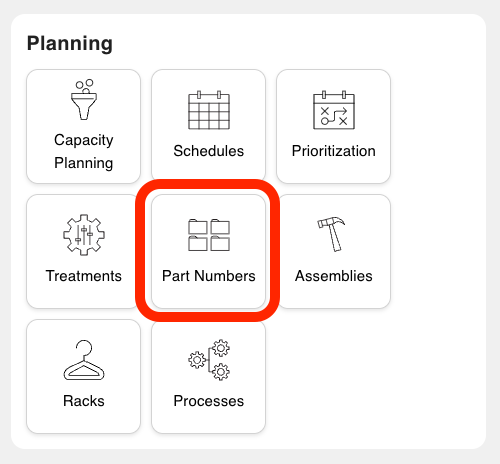

To configure Part Number Treatment time settings:

Navigate to the Part Numbers Tile from the "Planning" section on the Steelhead homescreen.

Enter into the desired Part Number Page and scroll to the "Treatment Times" section.

Click + NEW TREATMENT TIME.

Select the desired Treatment.

Set the default cycle time, total time, and pick the time type.

Click SAVE.

Part Number Station Treatment Time Settings

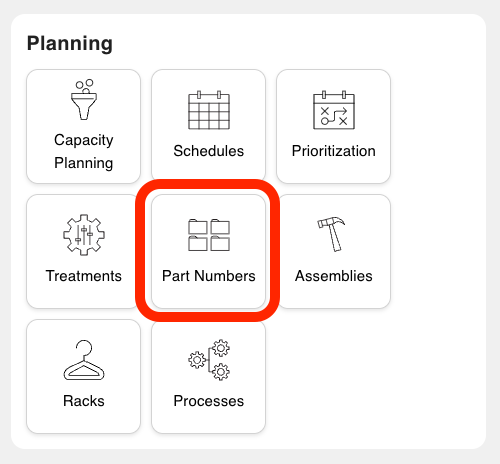

The top priority level of Treatment time settings is the Part Number Station Treatment configuration. This sets the time for specific Part Numbers entering specific Stations to complete specific Treatments. For example, if "3-IN-BOLTS" are being treated with "Blue" and "Spray Booth B", you can set the time for 11 minutes. This time will override any other settings previously configured.

Navigate to the Part Numbers Tile from the "Planning" section on the Steelhead Homepage.

Enter into the desired Part Number Page and scroll to the "Treatment Time Overrides" section.

Click + CREATE STATION TREATMENT OVERRIDE.

Select desired Station.

Select desired Treatment.

Set the default cycle time, total time, and pick the time type.

Click SAVE.

--