- Print

Work Order Margins

- Print

The Work Order Margin is a financial display menu that shows monetary statistics about a Work Order. To access this page a User must have the "Write: Financials" permission toggled on from their User Page.

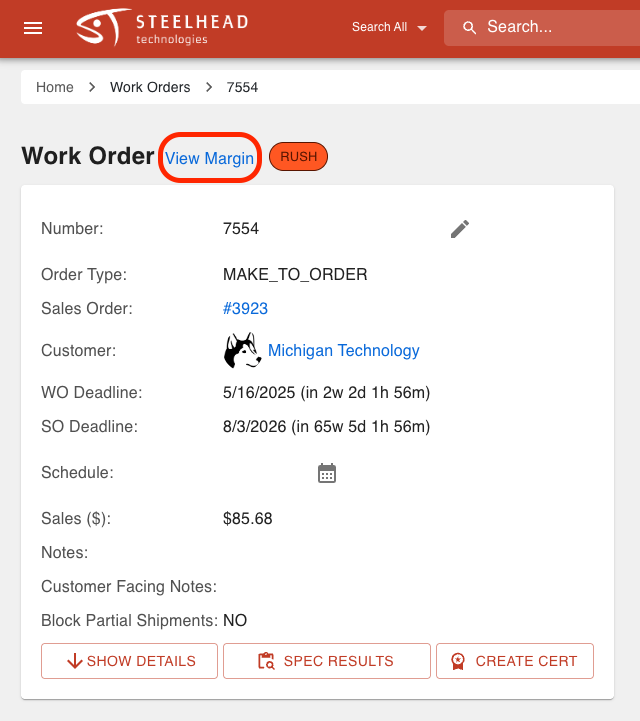

Viewing Work Order Margins

The hyperlink to view a Margin is available for every Work Order in your domain. Navigate from the Homepage to the Work Orders Dashboard. Open a Work Order Page by clicking on the number of one Work Order from the list. Click View Margin next to the "Work Order" title at the top of the Work Order Page.

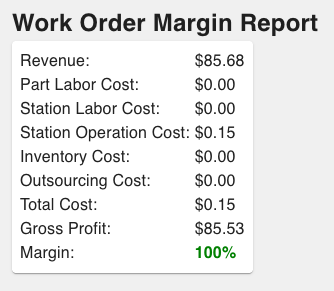

Work Order Margin Report

The list in the first display window on this page shows an outline of different costs attached to the Work Order.

- Revenue

- Income generated from sales or services before any costs or expenses are deducted.

- Part Labor Cost

- Shows the direct labor costs associated with manufacturing the Part.

- This is collected from users starting and stopping Timers on a job.

- Station Labor Cost

- This is the cost accrued from Users clocked into a Station that the Parts transferred through.

- Station Operation Cost

- Cost of operating a Station in the manufacturing process, excluding labor costs.

- Inventory Cost

- The cost incurred in Inventory-related operations like material consumption.

- Outsourcing Cost

- The cost incurred by outsourcing additional work for this Work Order.

- Total Cost

- The cumulative total of all costs for this Work Order.

- Gross Profit

- The difference between Revenue and the Total Cost.

- Margin

- The gross margin is the gross profit divided by the revenue.

To quickly see User and Timer info:

- Enter into a Work Order page and click "View all Billed Hours".

- Sort labor hours by Station to find out which of your workers had Timers running and for how long.

- Also, you can click on any of the ID numbers under Part Transfers Labor and it will pull up more information that may help you.

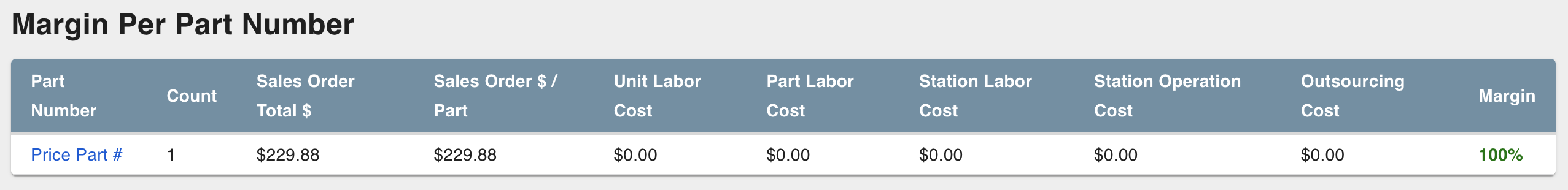

Margin Per Part Number

This display window separates out the margin data by Part Numbers in the Work Order in a table with these columns:

- Part Number

- Count

- Quantity of Parts that are on this Work Order.

- Sales Order Total $

- The total value agreed upon for the Sales Order that contains this Work Order.

- Sales Order $ / Part

- The amount of the Contract Total $ that will be divided out to each Part on the Sales Order.

- Unit Labor Cost

- Total labor cost divided by the total quantity of Parts on the Work Order.

- Part Labor Cost

- Shows the direct labor costs associated with manufacturing the Part.

- This is collected from users starting and stopping Timers on a job.

- Station Labor Cost

- Total labor cost of employees that are clocked into a Station while those Parts transferred through.

- Station Operation Cost

- The cost incurred by operating the Station while the Parts were at the Station.

- Outsourcing Cost

- The cost incurred by outsourcing Parts.

- Margin

- This is the Total Part Number Cost divided by the Sales Order Total Price as a percentage.

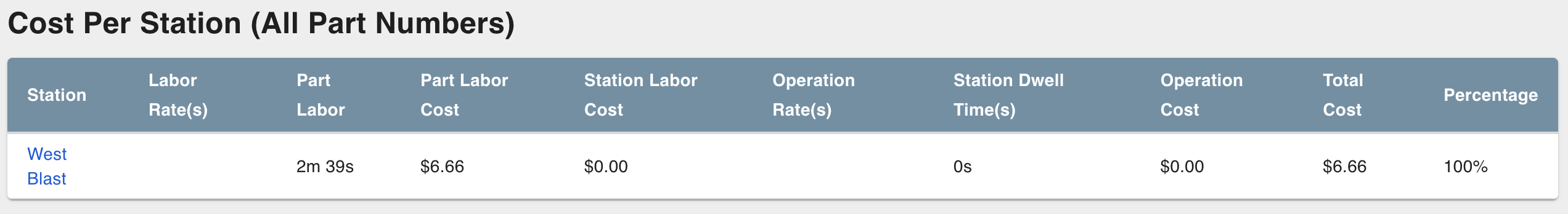

Cost Per Station (All Part Numbers)

The final table shows pricing data for every Station involved in processing the Work Order. If Parts pass through a Station without using Labor Timers, the numbers will all appear as zeros except for the Station Dwell Time. Timers must be used to calculate the numbers in this section. Its columns are:

- Station

- Labor Rate(s)

- Rate of labor pay for this Station.

- You can edit labor rates if you go to the Station itself.

- Part Labor Hours

- Amount of time spent treating one Part in a Process.

- Part Labor Cost

- Shows the direct labor costs associated with manufacturing the Part.

- This is collected from users starting and stopping Timers on a job.

- Station Labor Cost

- The total labor cost coming from Users clocked into the Station.

- Operation Rate

- Hourly rate of pay at the Station.

- Not to be confused with Operator Rate, the hourly rate of pay for an operator across all Stations.

- Station Dwell Time

- The duration that a Part spends at this Station on average.

- Operation Cost

- The cost incurred by running this Station.

- Total Cost

- All costs incurred by all Station.

- Percentage

- Percentage of the Total Cost taken up by the Station.

Rate Calculation

- Your Labor Cost is calculated by how much you are paying your employee to do this work multiplied by the Part Labor (the employee Timer on the station) .

- You can edit employee labor rates if you go into each User individually. This rate will be used over any labor rate which is set at a Station:

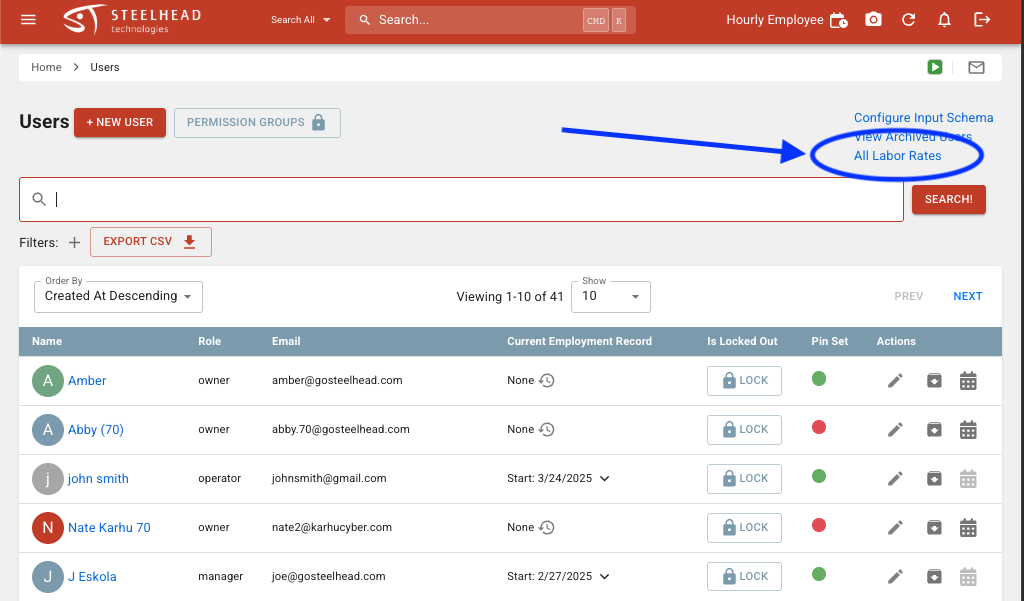

- Click on the User Management Tile from the Workforce Section of the Homepage.

- Click on Labor Rates to add or edit rates for any employee, or click on one User Name to make a change individually.

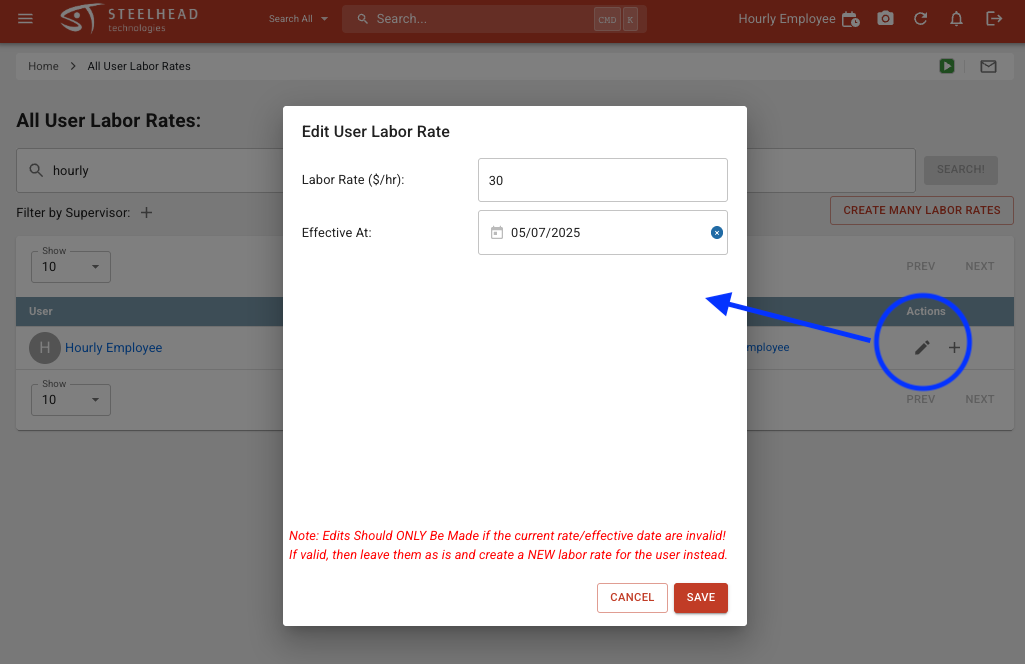

- From the Labor Rates page, click on a User's edit pencil icon to add a rate or make a change.

- You can edit employee labor rates if you go into each User individually. This rate will be used over any labor rate which is set at a Station:

- Your Part Labor is how long your employee had a Timer going on the Station.

- The Part Labor Cost is calculated by the Labor Rate x Part Labor.

- To have part labor cost you need to have a labor cost on your employee or else set on the Station and time going on a Timer for the employee.

- The Station Labor Cost equals the Station Dwell Time (total time of Parts in Station) x Labor Rate.

- The Operation Rate calculates how much it costs for your Station to be running.

- The Station Dwell Time is the total time of your Parts in the Station.

- Your Operation Cost equals the Operation Rate (how much the Station costs to run) x Station Dwell Time.

- Your Margin is how much you profit on this order, which is calculated by 1 - (the total cost/the price).