- Print

Treatment Troubleshooting

- Print

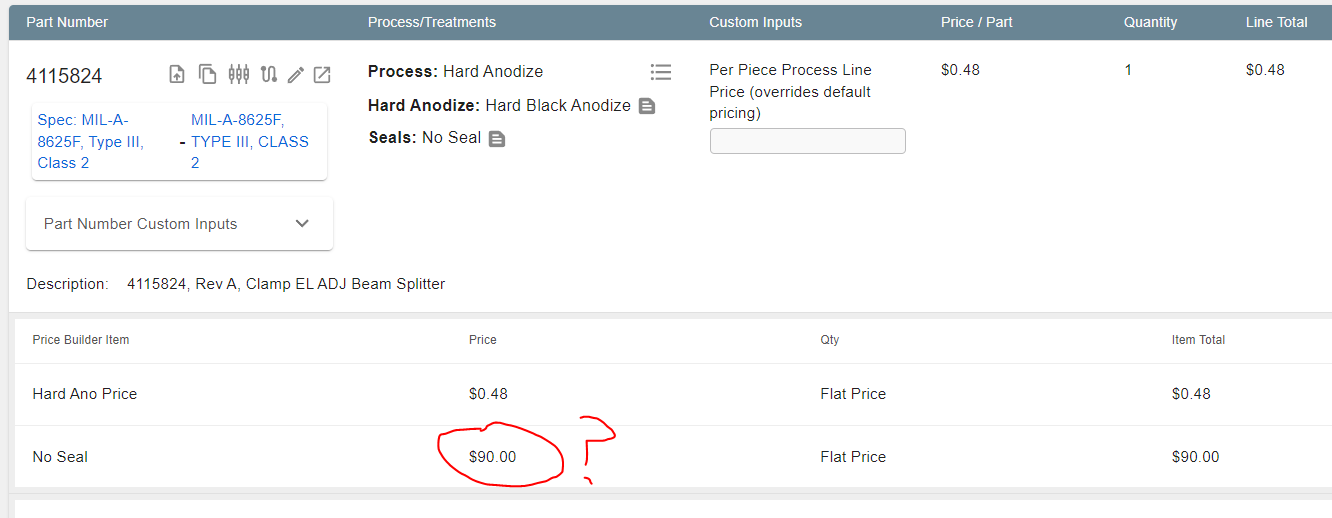

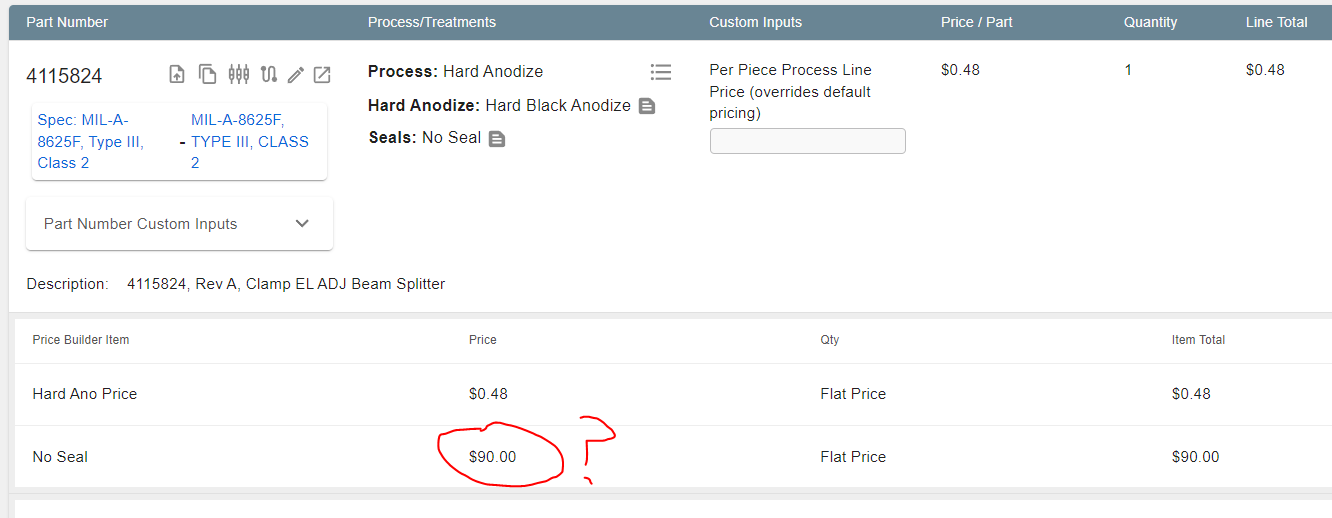

Flawed Treatment Price

If you see a price on a Treatment where it shouldn't be, here are some things you could try:

- In this example, a flat rate has been incorrectly assigned to this "No Seal" treatment.

- This can be corrected by visiting the Treatment's page and deleting the price from the prices list.

The price on the Part Number is a "global" price. So if you change the Part Number price for part ABC from $10 to $12, any new order will now charge $12 per Part. If you want a specific order for Part Number ABC to charge $15 per Part, you would change the Part price in the Sales Order. That would only affect the price in the Sales Order that it was entered in.

However, when you add or change a price in the Part Number dashboard, it will update globally for everything new that is created with that Part Number. It will not update globally for Sales Orders etc. that already existed.

Treatment misapplied to a Work Order

If your Work Order is showing the wrong Treatment, here are some things you could try:

- In all likelihood someone mistakenly switched the Treatment and it should be corrected.

- To edit the Treatment override, under the Sales Order, click the pencil on the right of the Part Number and change the Treatment (you will also need to do this if you want to correct the Station assignment)

- To edit the Treatment override, under the Sales Order, click the pencil on the right of the Part Number and change the Treatment (you will also need to do this if you want to correct the Station assignment)

The remedy will be similar for Work Orders that don't have a Treatment attached. Make sure Work Orders that aren't progressing as expected have a Treatment attached.

Inventory Item Unavailable in Processes

If you are not able to find an Inventory item when creating a Process, here are some things to try:

- In all likelihood the Inventory Item was not added to the Treatment connected to this Process.

- To fix this, go to the Inventory Item's page and scroll to the Treatments section to enter the Treatment matching your Process.

- Because the drop-down list does not load all the (potentially hundreds of) options (by design), you'll likely have to prompt it by entering some search text first.

Parts Automatically Switching Work Orders

If your Parts are moving onto different Work Orders when they shouldn't be, here are some things you could try:

- If you do have two Parts that should be going through the same Process, when you add them to the Sales Order it will list what Work Order each will be associated with.

- Below you can see that these parts are going through the same Process and same Treatments but are showing up on separate Work Orders.

- This is because they have different Nodes selected as opt ins, or opt outs, meaning they aren't going through the same exact Process, step by step, and can't be run together.

- But if you keep an eye out on this screen you can catch this before the order is created by clicking on each Part Number and checking the defaults.

To quickly see this User and Timer info:

- Go to the margin report on your Work Order and choose a Station.

- See labor hours at Station to find out which of your workers had Timers running and for how long.

- From here, you can click on any of the ID numbers under Part Transfers Labor and it will pull up more information about the User and the Timer.

Adding a New Material to Treatments

If you would like to add a new material to Treatments (for example, a Customer supplies the paint they'd like you to apply):

- In the Inventory module, select the Inventory Type.

- Click +ADD ITEM.

- Complete the "Create Inventory Item" dialog, and SAVE.

- Return to the Treatments module, and use +ADD/EDIT INVENTORY ITEMS FOR TREATMENT to associate the material with the Treatment.