- Print

Setting Specs

- Print

Technical Specifications (Specs) can be accessed and managed from the "Specs" Tile, located in the Quality & Compliance Section on the Homepage.

Adding New Specs and Spec Fields

On the "Specs" dashboard, click the "New Spec" button.

Name the Spec and click "Save".

From this page, you can edit the spec description using the "Edit" button, or add spec fields using the "New Spec Field" button.

Adding a new spec field gives you the option to name the field and identify its type such as number, boolean, etc.

- "Number" specs are for recording measurements, quantities, or other data that can be stored numerically.

- "Boolean" specs are stored as either/or inputs. Booleans are good for spec data that asks for these sorts of inputs:

- Yes / No

- Pass / Fail

- True / False

Click "Save" to create the spec field.

Once the spec field is created, click its name to set up parameters for the spec field.

- For all specs, give the parameter a name, description, and sampling rate.

- The "Input Required" checkbox will require input for the spec field when moving parts.

- The "Request Document" checkbox provides a space to upload an external document (picture, file, etc.).

- The "One at a Time" checkbox can be checked for measurements that will be entered in individually.

- For "Number" type specs, identify minimum, target, and maximum values for the spec where necessary.

- For all specs, give the parameter a name, description, and sampling rate.

The spec field parameter can be edited with the pencil icon or permanently deleted with the trash can icon.

A sampling rate of "1" means that every part is measured. A sampling rate of 0.1 means that 1 in 10, or 0.1 of the parts, are measured. A sampling rate of 10 would indicate that each part is measured 10 times.

One at a Time

Some measurements are taken for batches (oven time and temperature for a batch; tank pH; etc.), while some are taken on individual parts (finish thickness, quality inspection, etc.) Choosing "One at a Time" for the spec field can make data entry much easier if you enter data for multiple individual parts all at one time.

[EDIT SPECS] button available on WOs

- This button can be used by those with the "Archive: Spec Measurements" user permission.

- Use the [EDIT SPECS] button to review specs, spec fields, and params.

- NOTE: editing the specs of a part on a work order will change part specs/parameters only for that instance. The changed specs will not apply to the same part number on other work orders.

Non-Linear Sampling Rate:

- Users may set non-linear sampling rates for their params

- These are based on minimum and maximum batch sizes

- This should allow for more flexibility for sampling

- How to use this feature

- Go to the specs page

- Click the sampling link

- Add new sample set

- Go back to specs page

- Create a spec and apply some number spec fields

- Apply your desired params and choose the new sample set

- Apply spec and params to part number or treatment

- Create sales orders

- Add parts to a work order

- Step through to where the param is

- Notice sampling requirements

Minimum Effective Parameter Range

When you create a numerical spec field with "Type" designated as a Number, Sensor/Number, or Timer, you are able to specify a minimum effective parameter (param) range. This setting should be the total effective "tolerance" of the spec field measurement. After you set and edit params (outlined below), you will be prevented from racking parts together if the spec params are not set with ranges which overlap widely enough to accommodate the minimum effective range.

Setting and Editing Params

Steelhead enables easy editing of spec field params values when setting specs on a quote part:

- Add a spec to a part number or click 'Edit Part Number/Add Specs' from a quote line.

- Use the UI to edit spec field params min, target, max values.

- Toggle to use tolerance at the column header.

- Lines highlighted blue have changes that are ordered appropriately and can be saved.

- Lines highlighted yellow have changes that can’t be saved because the target is not in the min & max.

- Click Save Changes on the bottom banner and ensure spec field params are saved.

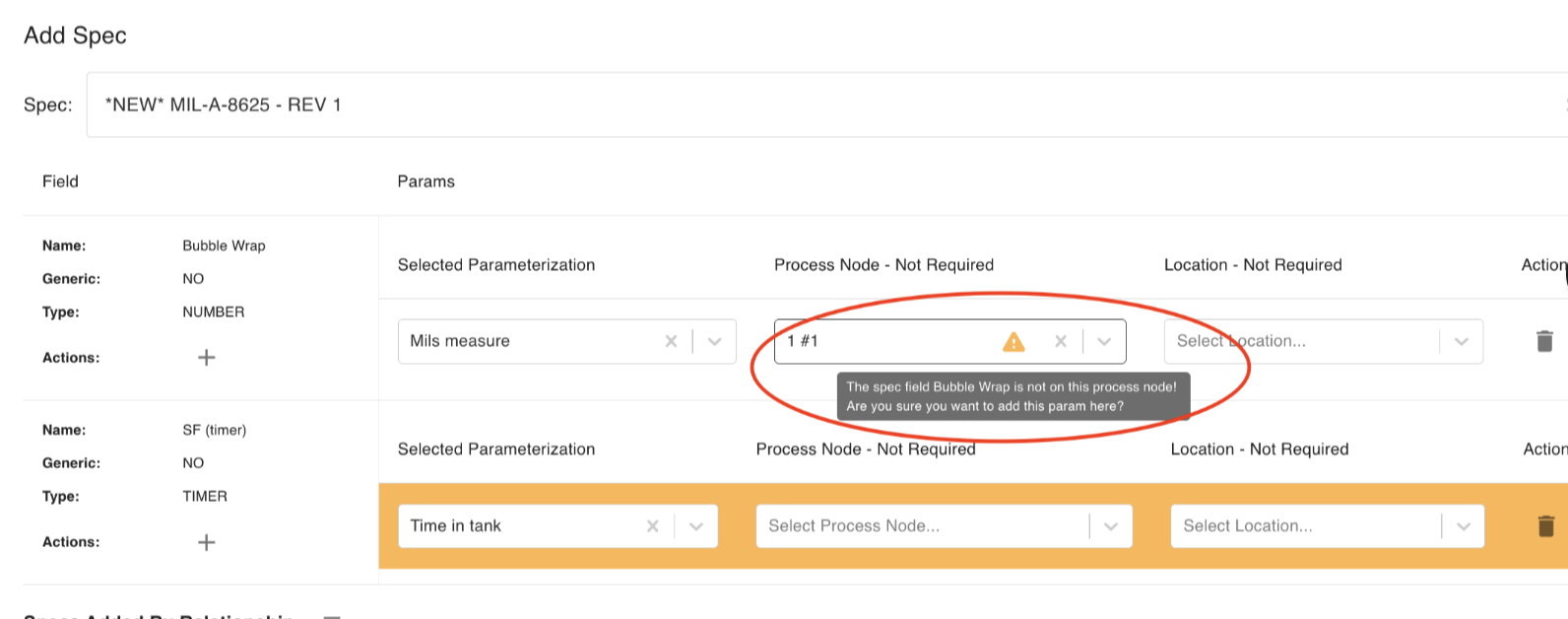

This is what you should do to resolve errors like the one shown below:

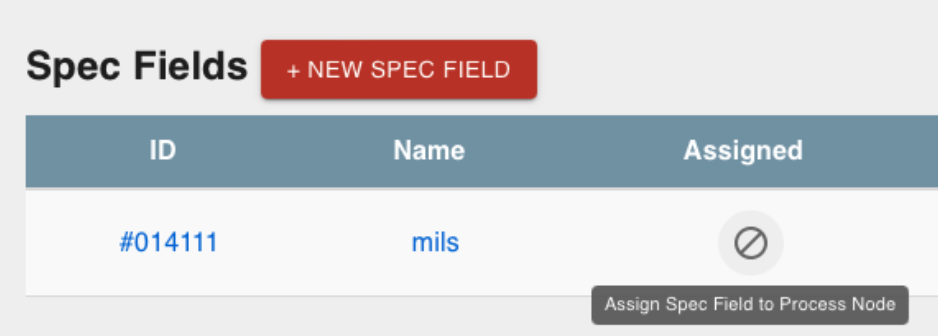

Some options relating to viewing specs on the process they are attached to:

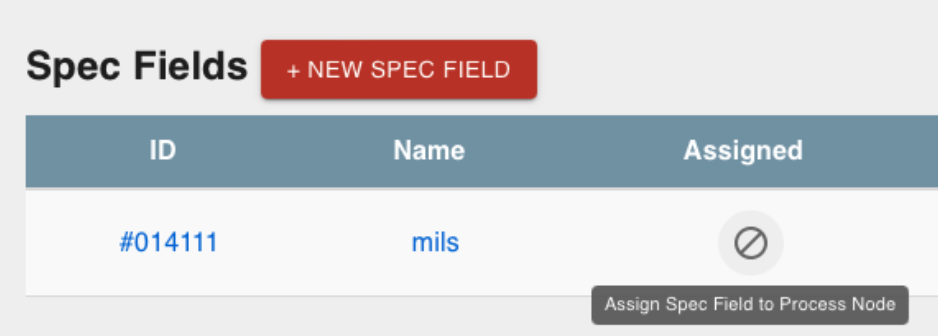

- Attach a Spec Field to a default process by clicking its slashed circle icon on the Spec page.

- View spec fields attached to the default process by clicking link icons near the process tree.

- View process nodes attached to a spec field by clicking the link icon on the Spec page.

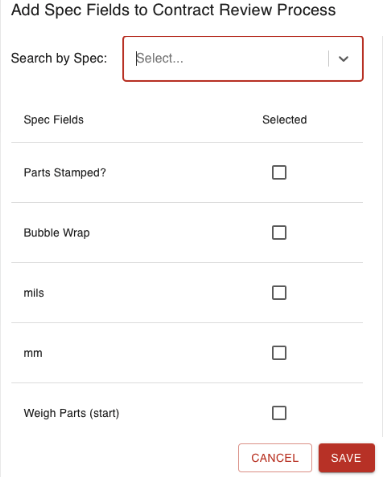

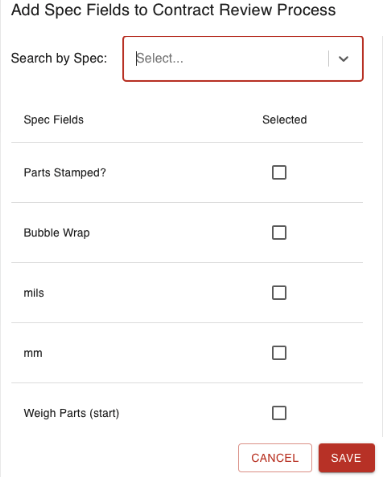

- Add Spec Fields to a Process Node by selecting them directly or using the spec search.

- On a Process Node with a Spec Field, click the Spec Field row to view more information.

Non-Required Process Node Param:

When adding a spec to a part number or changing it, if a new process node (different to what is already assigned) is added, that spec field will apply to that node for all future orders that include that spec/spec field.

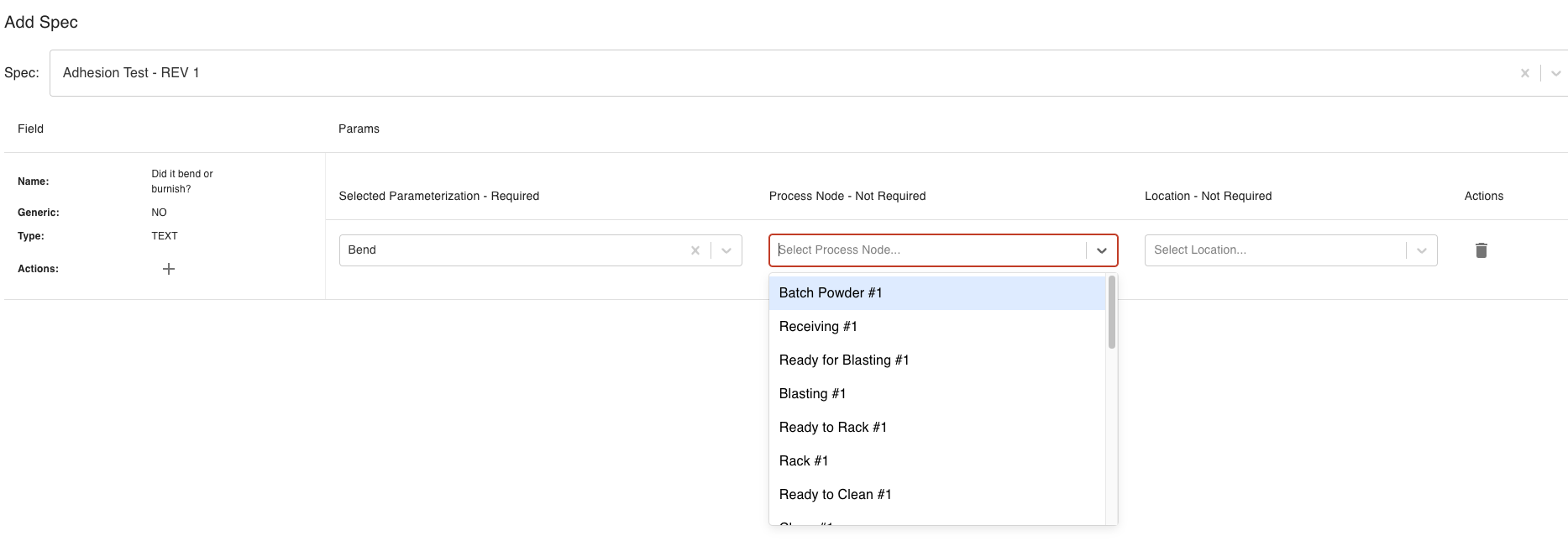

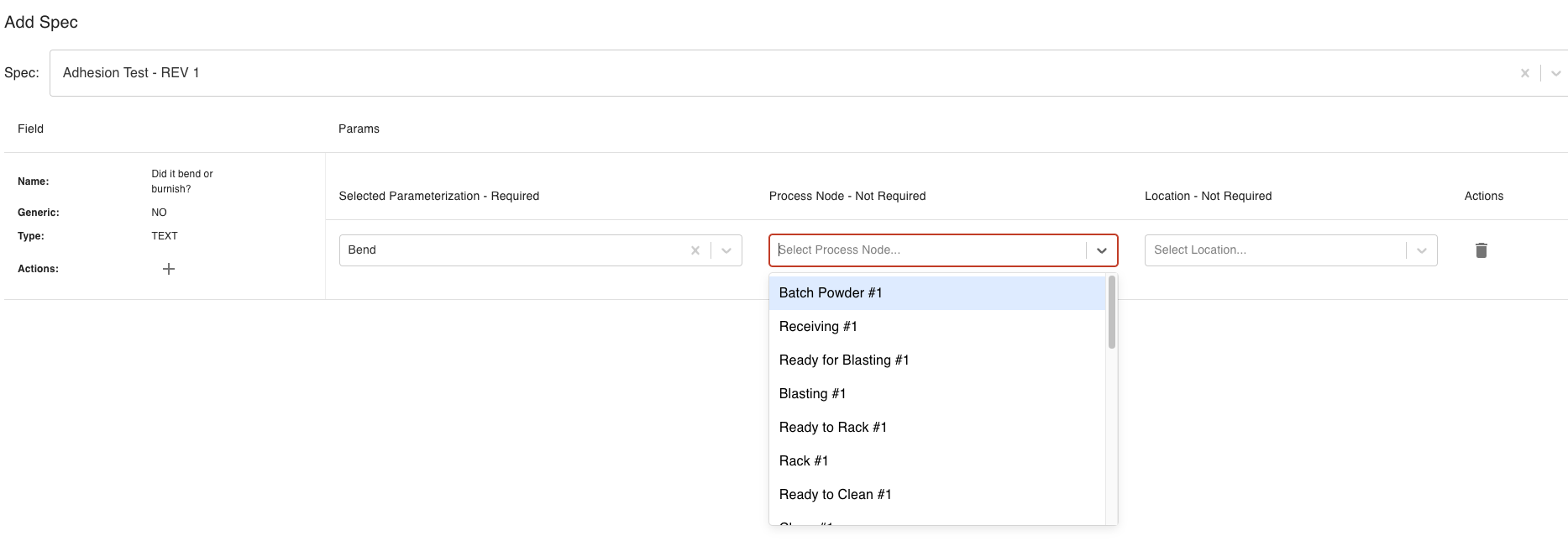

- For example, below is the screen that comes up when you try to add a spec to a part number specifically.

- When you select the param you also can select the node as well (as seen in the drop-down).

- If a different node than what the param is already assigned to gets selected, Steelhead will add that param to that process node.

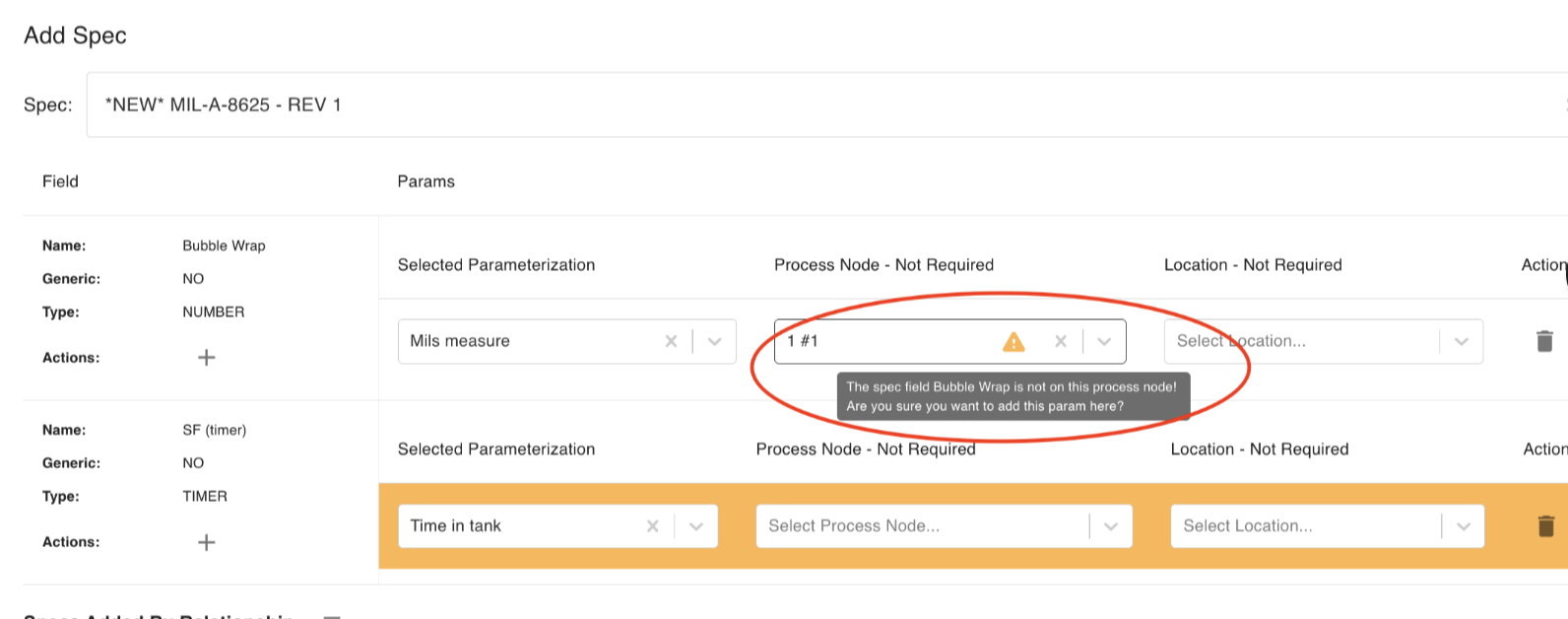

When a param is being added to a recipe node on a work order, if a different process node is selected, a warning will populate to let you know.

- But also, if you do still add it to a different node, it will only add the param to that recipe node for that specific work order if you are editing the specs/part number from a work order.

Allow For Grouped Spec Inputs on Workboards:

Users may enter spec measurements for multiple parts on one panel.

They can also temporarily group parts on a workboard card and enter measurements for all parts that need measurements.

- Find/Create a workboard.

- Find/Add a card with numerous parts that have spec requirements at this stage.

- Select either Group Like Parts or Toggle Multiselect on the card or global filters.

- Observe that the parts are now in collapsed drop-downs with one at the top that says: "More Measurements Required".

- Click on the "Enter Specs" button.

- Enter the spec measurements for the parts. When you close the panel, the parts should be moved into other groupings and be ready to move.

- Repeat steps 1-4.

- Use the multiselect toggle to select multiple parts.

- Click on the "Enter Specs" button in the red row at the top of the card.

- Repeat steps 6-7.

Table Feature for multiple geometric measurement spec records on a single part

For specs that are recorded across multiple nodes at different geometric points, the specs Table feature will preserve numerical data entered at previous nodes for data repopulation, and will calculate differences or sums (for example, for thickness gain during one treatment) and warn if those changes exceed your set parameters.

To use the Table feature, create or edit a numerical spec on a part (a reference), with a distinct name.

Then create another spec in the same way (a referencer), with the addition of selecting the name of the reference spec in the drop-down "Referenced Spec Field."

Both the reference and referencer must have Spec Field Params created with the following characteristics, in addition to your own guidelines:

1. Minimum and Maximum values

2. Sample count per Batch = 1

In addition, the referencer must include an Operation Parameter selection: addition or subtraction

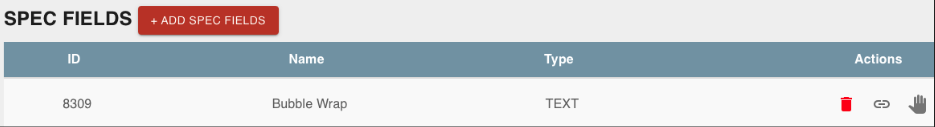

Click to the same Part Number's Geometry Type, and click to Geometry Type Spec Field Properties. Click "+NEW PROPERTY" to create a new measurement spec field location. Use specific property names, i.e. "outside diameter", "inside diameter", etc. Each new Geometry Type creates a row on the spec field table for that part.

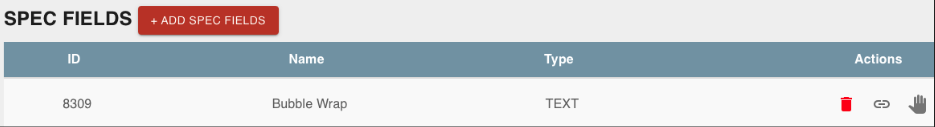

Back out of Spec Field Properties, to the Part's Geometry Type, and use "+ADD SPEC FIELDS" to attach the multi-spec field to the part (or create new designations). Use the "+" icon to assign each property (in this example, "outside diameter" and "inside diameter") to the spec fields.

On a Work Order which includes a Part with your Geometry Type multi-measure spec, add the referenced and referencer specs to the Nodes where the data is collected, and click Save. Move/Work the parts to the first Node/first Spec, and you will see the table you've just created.

Enter the spec values. The values you enter at each geometric "Property" will then carry over and display on the table at the next spec-managed node as "Past Value." When you then enter "Current Value" for the spec at the current node, a calculation based on your operation parameter will be shown, along with pass/fail information. The calculated values will also be shown when you click on "Spec Results" for these parts.

Setting Specs videos:

https://www.loom.com/share/be5e6ba362f341f2ad2c94646f2a7380

https://www.loom.com/share/d0610b690e264e65ba9283b24494748b

https://www.loom.com/share/0c8d8d815fa14c53b236496758094a87

--