- Print

Red Line Job Costing

- Print

Overview of Red Line Job Costing

With the Red Line job costing system, every part is accounted for by the system when it crosses over a "line in the sand" somewhere on the auto line, and allows all costing to associate with that red line.

Setting up the System

First choose a Timer, then specify a Part Number on a Work Order that should be on this red line for a specific amount of time. Comparing this to the cost it takes to run your line per hour is what would tell you the cost and help determine margins. To enable red line, the first thing to do is set up Stations that will be using it.

Note that because Red Line is a feature designed for Auto Line Timers, it can only be applied to Super Nodes.

Allow Costing

To begin, you should have powder auto line and red line costing mode turned on. In edit station, you can determine whether or not you would like to set a red line job costing on or not.

- If red line is not selected, we fall back to the default job costing method.

- This method is defined by User timers and Part Transfer times.

To open the Edit Station menu, you can use this button on the Workboard:

Apply to Station

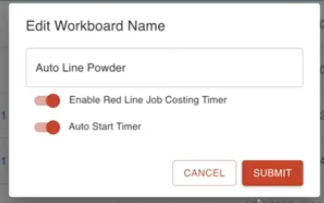

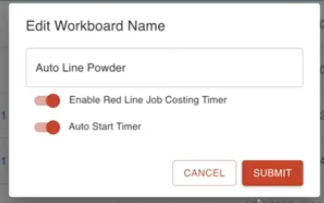

Once this is set up, go to the Workboard where using the Auto Line Station, and apply the red line setting onto whatever Workboard Card that is going to have it.

- To do this, click Edit and enable the red line job costing timer.

- Once this is set up, new timer options should appear in the auto line powder node.

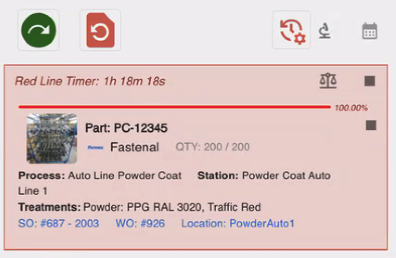

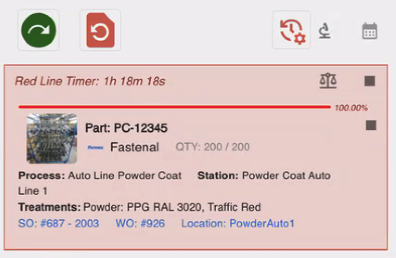

- Then we can start a timer for this part on the red line.

- Then we can start a timer for this part on the red line.

Using Red Line

- The red line should only be in one place on the station.

- Steelhead allows only one active red line timer per station.

- In order to use the red line, start the timer on the part as it crosses the red line.

- When it leaves, pause the timer (by clicking stop or by starting a new timer).

- When the Part passes the red line, hit the green NEXT button.

Editing Red Line Timers

- To edit the timer you have set up, click the Scale icon and see the editing menu page.

- This will allow you to proportion the cost of the red line timer between the different parts in the station.

- The DISTRIBUTE COST button will automatically calculate a proportion based on the part count shown.

- This will always happen by default if you don't choose to edit the timer.

To edit many timers at once, select the clock with a gear icon and take a look at the menu that appears:

Along the top you will see selection buttons that will highlight different amounts of time, including:

- Last 30 Minutes

- Last hour

- Last 2 hours

- Auto-Scale

- Isolate selected

Along the side you will see a checkbox for every different part that is on the clock.

More Info:

- Monorail auto/semi auto lines

- PNs must be loaded sequentially (1 PN at a time)

- Total cost/hour of the whole line must be known

- 8 hours daily load time

- $1,500 labor + $500 utilities + $300 maintenance = $2,300

- $2,300/8 hours = $287/hour

Steelhead will monitor the PRECISE TIME that a Part Account passes over the red line.

- In the margin for Work Orders treated with Red Line, all of the labor operation cost is directly calculated from the time that that part occupied the red line, so it defines operation cost per hour on the station.

- By default, take the time that that part occupied your red line to see the cost for this PN on that station.

- However, Steelhead can do labor costing with the red line as well.

- It's best not to assign the red line at the exact spot where the labor is occurring.

- However, doing so may still operate if necessary because that part occupying this time is read by the computer as occupying the whole line and logging it to the workers who are clocked into the line.

- Therefore, it costs more per minute to occupy the line because there's more employees working the line.

General Job Costing Info

Job costing with margins super useful for things like seeing who works the most efficiently at stations for station planning, what areas need to start working faster or where we could actually spend more time and be more thorough.

A good start would be going into each station in Steelhead (or your most commonly used ones) and be sure that they have

- A station operation cost

- What does it cost on average per hour for you to use that machine?

- A station labor cost

- Labor cost is based on what you pay your employees.

- So if you average paying them $20 an hour you would put $20 there and if any of your employees have their own labor rates in their account, that labor rate will override your station labor rate).

From there just make sure your employees are using their timers accurately so you can see how much it is costing for them to be running the parts at the station and your operation cost will calculate automatically based on the time the parts spent in the station.