- Print

Part Number Troubleshooting

- Print

Flawed Data Fields for Part Stepping

If entry fields for moving Parts between Stations (like racking and cleaning) are not accepting data, here are some things you could try:

- You may need to archive extra measurements in the Process.

- The Part Numbers may be assigned to only one Customer.

- If so, they will only show up when making Quotes for that Customer.

- You can delete the assigned Customer from the Part Number and it will be available for all Quotes.

Part Number/Customer assignment

- If you search for this Part Number there may be no Customer selected for this specific Part.

- If there is not a Customer saved on the Part Number, this Part Number will be available for use for all Customers.

- If you create a Part Number from a Quote, the Part Number will automatically be assigned to the Customer that the Quote is for.

- However, the Customer can be removed from the Part at any time.

Show Quantity of each Part Number on Work Orders

If you would like add Part Number quantities to Part Number Inventory batches on Work Orders (so all parts show up on the same line of the Work Order), here are some things to try:

- If parts are received in a Part Number Inventory Batch you have to adjust the quantity from the MOVE PARTS Part Count +/- icon in the Work Order.

- If you just add new parts to the Work Order the parts will move separately.

Part Number Default Price

The price on the Part Number is a "global" price. So if you change the Part Number price for part ABC from $10 to $12, any new order will now charge $12 per price. If you want a specific order for Part Number ABC to charge $15 per part, you would change the part price in the Sales Order for that order. That would only update that Part price in the Sales Order. It would not update the price anywhere else.

However, when you add or change a price in the Part Number dashboard, it will update globally for everything new that is created with that Part Number. It will not update orders that already exist.

The Part Number price specified on a Sales Order line will override the price set to the Part Number itself.

Anytime you want to change the default price of a Part Number, follow these steps:

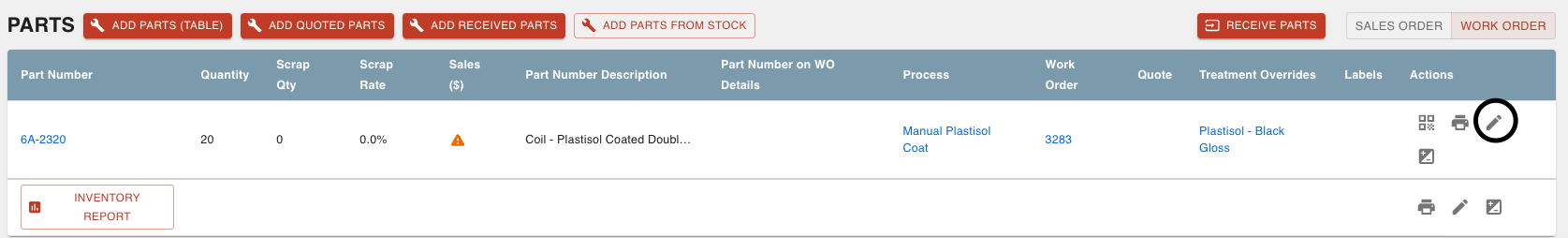

- Scroll down to Sales Order lines (this can be found under the "parts" and "Work Order" tables on a Sales Order).

- Choose the edit pencil under the line number and change the price/unit there.

If you want to know more Steelhead pricing information, review the article on Margin Pricing.

Modifying Part Number Description on One Work Order

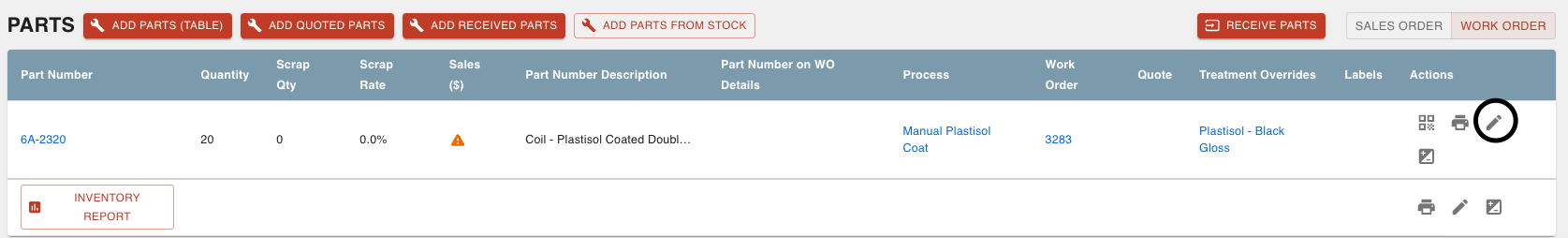

If you would like to modify the description of Parts for one Work Order:

- On the Sales Order, click the edit pencil icon on the far right of the BOM ITEMS Table Work Order line, and enter another description with the "Edit WO Details for Part" edit pencil icon.

Remove Duplicate Part Numbers

If you have unnecessary copies of a Part Number, those with incomplete information should be archived:

- the quick way to do this from the Part Number page is by selecting the "Archived" checkbox in the title card for the Part Number. Unintentional extra copies may be recognized by things like empty description fields, or information that is incomplete or not up to date.

If you have duplicated Part Numbers in a Work Order, it may look like this:

Click MOVE PARTS -> Transfer Type = EXIT on the Work Order Line with the duplicate Part Number.

Click MOVE PARTS on the line with the correct Part Number. For Part Count, click the +/- "Edit Part Quantity" icon and adjust the count.

Parts not Showing as Complete

If Parts or Work Orders are not completing, there might be a step left undone:

You may have completed the shipping, but not the Parts themselves, as shown here:

The warning lets you know that they will be moved to the next step in the Process which is Invoicing.

When invoicing is complete another dialog asks you to complete the Parts.

In invoicing you will only complete the number of Parts you invoice for. Example: If there are 1000 parts total, and 100 are past shipping and in invoicing, only 100 parts would be completed with the "complete parts" button on the Invoicing Dashboard.

Processes for Parts to run on Differing Systems

If you would like different Processes for jobs that can run on two different systems, here are some things to try:

- If you have the same Part Number but running different Processes and you want them on the same Sales Order, you just have to choose the Process when adding each group of Parts.

- If the order was already entered and you need to change the Process for the Parts, this example may be helpful:

- If you have 80 parts and 20 of them need to move onto a different Process:

- On the Sales Order, reduce the original quantity to 60. Then add another line with 20, and assign them to the second Process.

Extra Assigning of a GL Account

If General Ledger accounts are being used that shouldn't be, here are some things you could try:

- The extra account could've been accidentally added when you create a Part.

- You can change the attached GL in your Accounting Software.

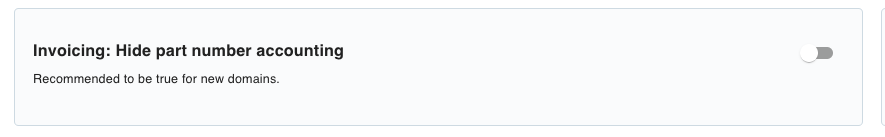

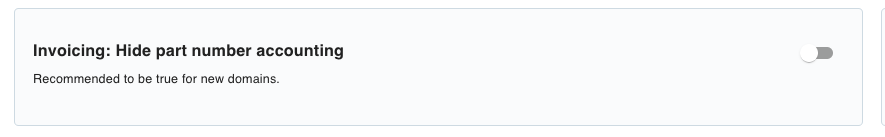

- If you do not actually use GL accounts with Part Numbers, create a copy of the Part Number, archive the first, and turn on the Domain Setting for "Invoicing: Hide part number accounting."

- This will prevent Part Numbers from syncing over if a match is found in accounting software.

- Accounting ID/Name is for Steelhead Users who invoice based on Part Number instead of Product price - so when the Part Number is synced to Accounting Software, the software fills in the accounting ID/Name.

- The accounting ID/name can be changed in Steelhead if this Part has not synced over to your accounting software yet.

- If it has synced over it will need to be edited in in accounting software, and that change will flow to Steelhead at the next integration sync.

- If needed, follow these steps for properly editing items in Quickbooks Software:

- Click Lists, then select Item List (for Windows) or Items (for Mac).

- Double-click the item you want to change.

- Edit the info for the item.

- Click OK.

Part Number Split into Multiple Lot Charges

If you notice unexpected lot charges, check if the Parts are being processed separately in Steelhead:

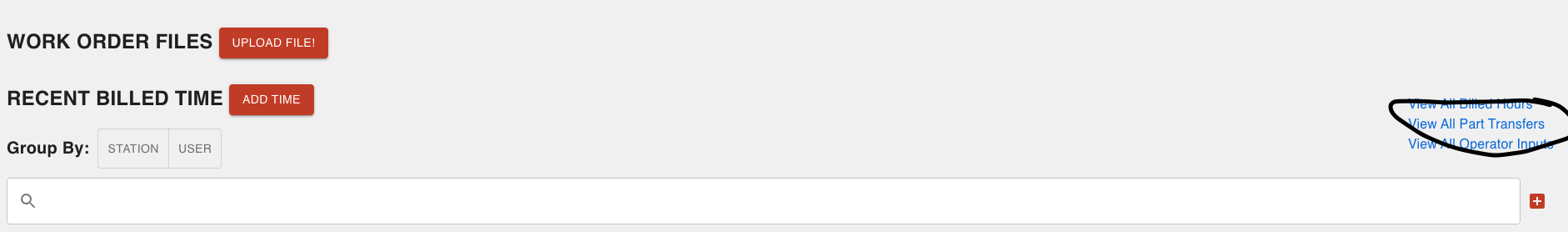

- Looking at the Part Transfers screen, it may appear that some parts move forward and not the others

- Normally they should be automatically combining back together if they are in the same Node.

To combine them together if this happens again:

- Use the box by the Part Number to MOVE PARTS.

- In the part count box click the +/- box and type in the total amount and it will say you are adding (n) parts.

- Save and submit.

- Then you will exit the other parts by clicking that same box to move multiple parts and in the transfer type you can EXIT the parts and they'll disappear.

'Part Numbers not Related to any Line Items' Error

If if this error is interrupting your workflow, here are some things to try:

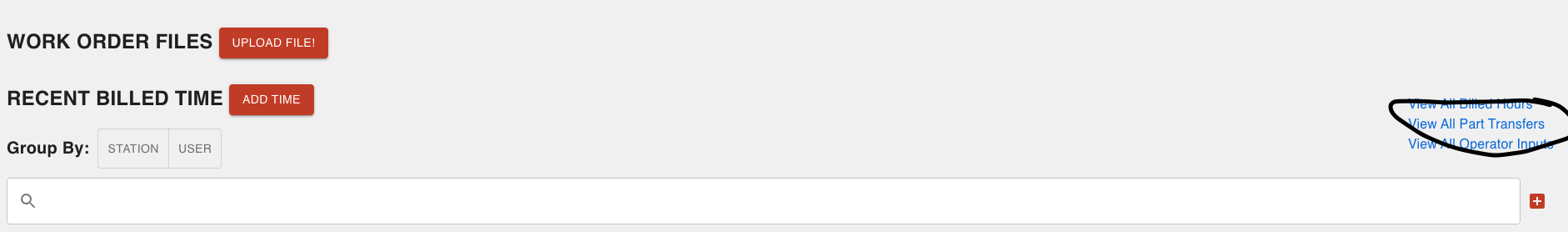

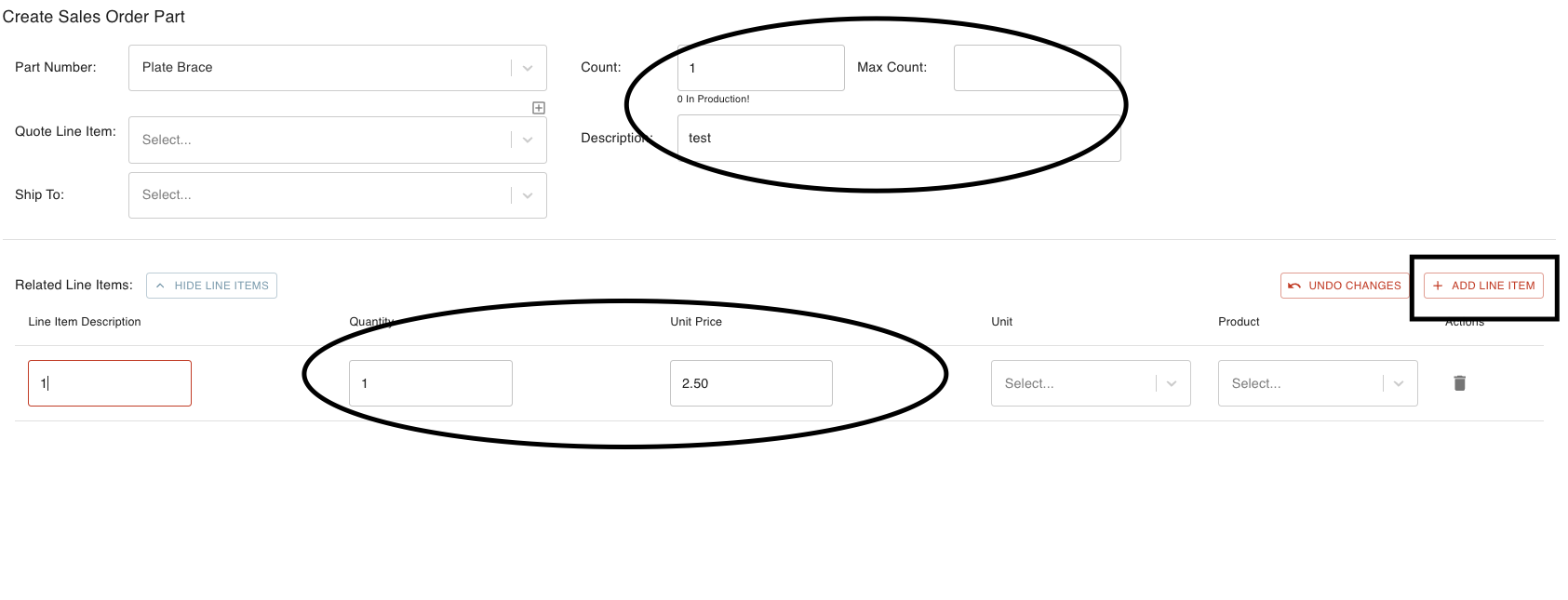

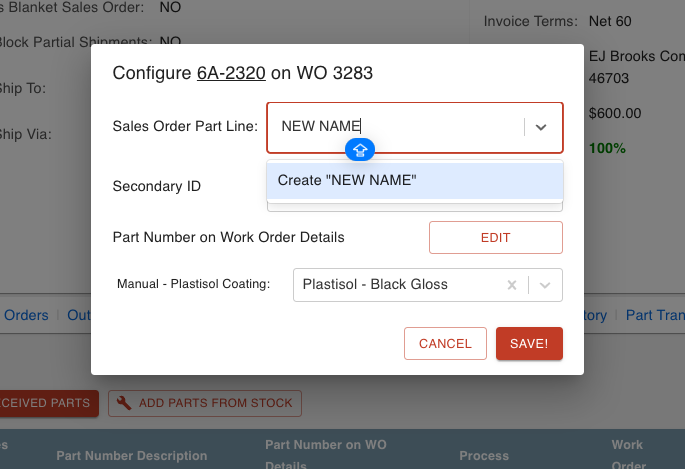

- This error is letting you know this Work Order part is not connected to a Sales Order line. To add this to a Sales Order line go into the Sales Order and click under the Work Order tab. See image below:

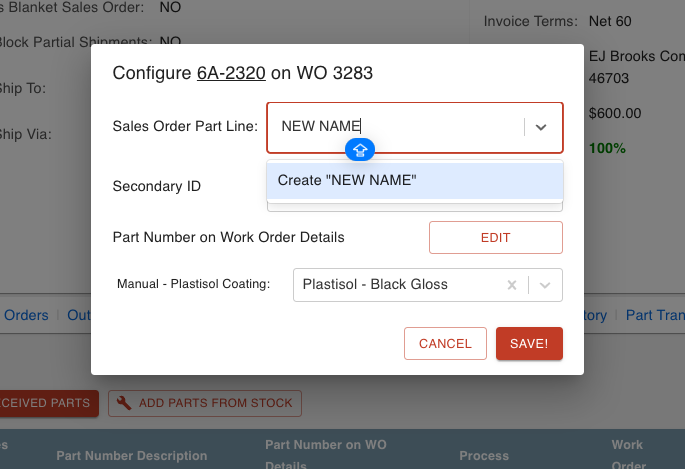

From there click on the edit pencil on the far right of the Part Number.

This is where you will create the Sales Order line, so start by typing in a new name for the Sales Order line and SAVE.

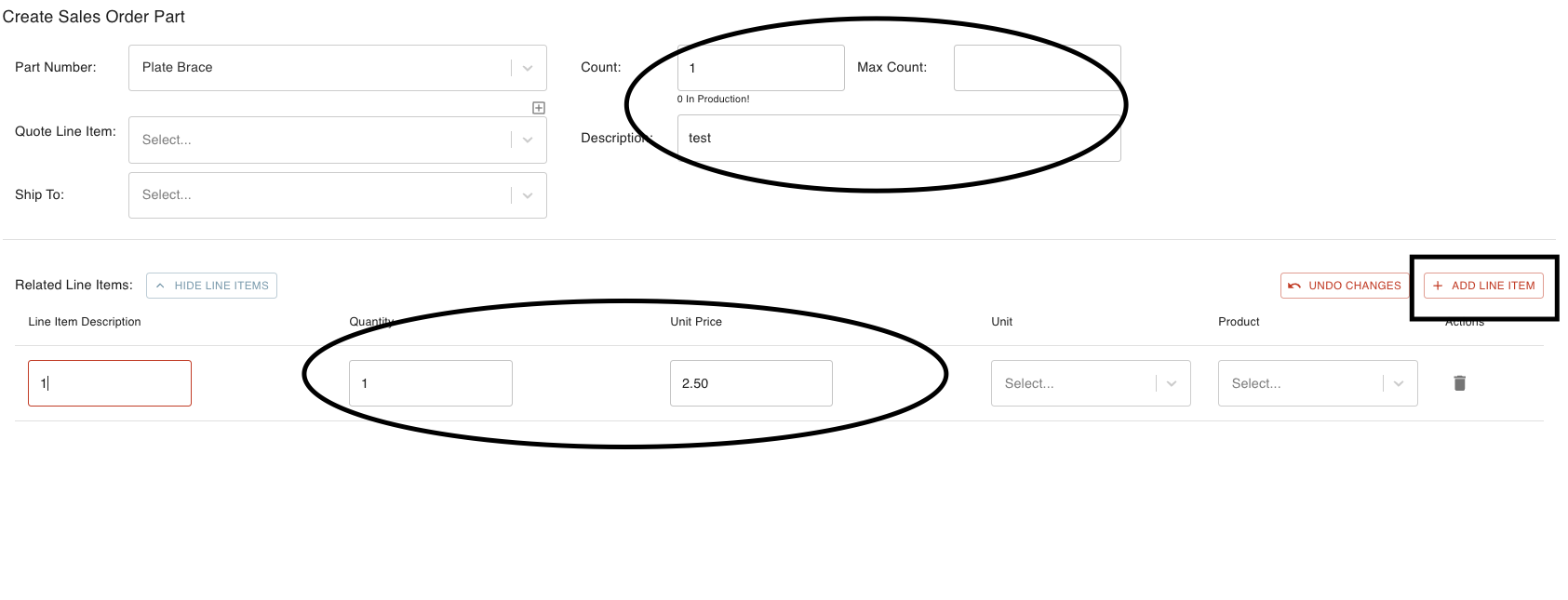

The next screen will have you enter in the quantity, you will also have to click 'Add Line Item'. Fill in the description, quantity, and price then SAVE.

When all this have been entered and saved, this will connect the Work Order part to a Sales Order line.